Chloroprene rubber, also known as neoprene, is a synthetic rubber made by polymerizing chloroprene, a monomer derived from chloroprene gas. It was first developed in the 1930s by DuPont scientists and is now widely used in a variety of applications due to its excellent physical and chemical properties. Chloroprene rubber is known for its resistance to oil, chemicals, heat, and ozone, as well as its good weatherability and durability. It is commonly used in the production of wetsuits, gloves, electrical insulation, automotive belts and hoses, and other industrial applications where its properties are desirable. Additionally, neoprene foam is often used in the production of insulation materials, orthopedic braces, and other consumer products due to its excellent cushioning and shock-absorbing properties.

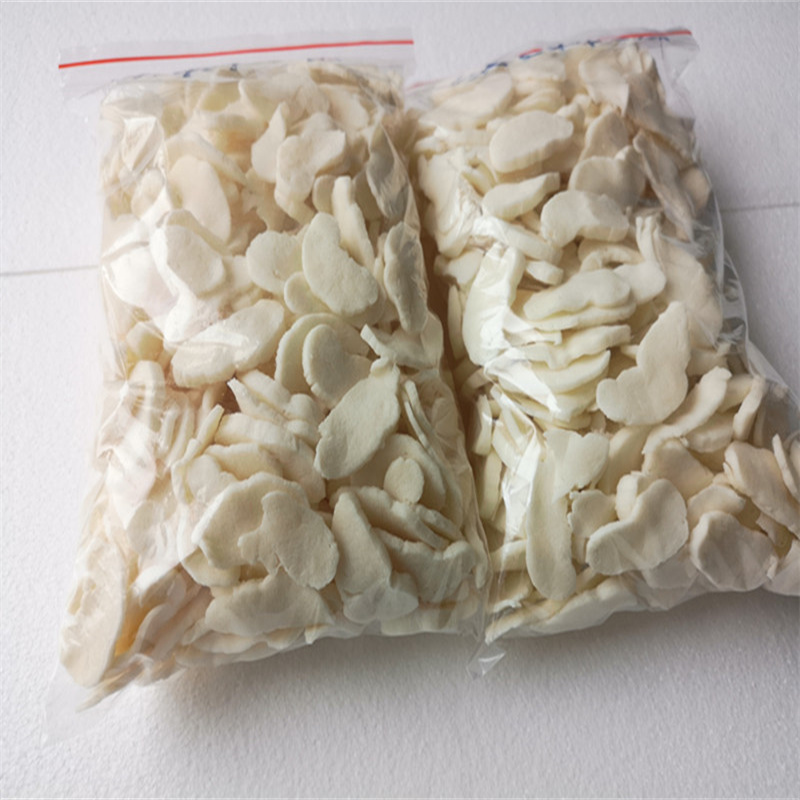

Appearance: Milk white chips.

Application:

For making Chloroprene adhesives. The Chloroprene adhesives are used for bonding rubber, leather, fiber, metal, wood, cement products, Shoes, Furniture, Toys, Handicrafts, Mattresses etc.

Packing: Packed in bags, 25kg net weight each.

Shelf Life: One year below 30¡æ from the date of production

Property:

|

Item

|

Index

|

|

Viscosity in 5% toluene

solution, mPa.s

|

CR 2441

|

25-34

|

|

CR 2442

|

35-53

|

|

CR 2443

|

54-57

|

|

CR 2444

|

76-115

|

|

CR 244A

|

116-140

|

|

CE 244B

|

¡Ý 141

|

|

Peel Strength, N/cm ¡Ý

|

90

|

|

Volatile,% ¡Ü

|

1.5

|

|

Ash,% ¡Ü

|

1.5

|